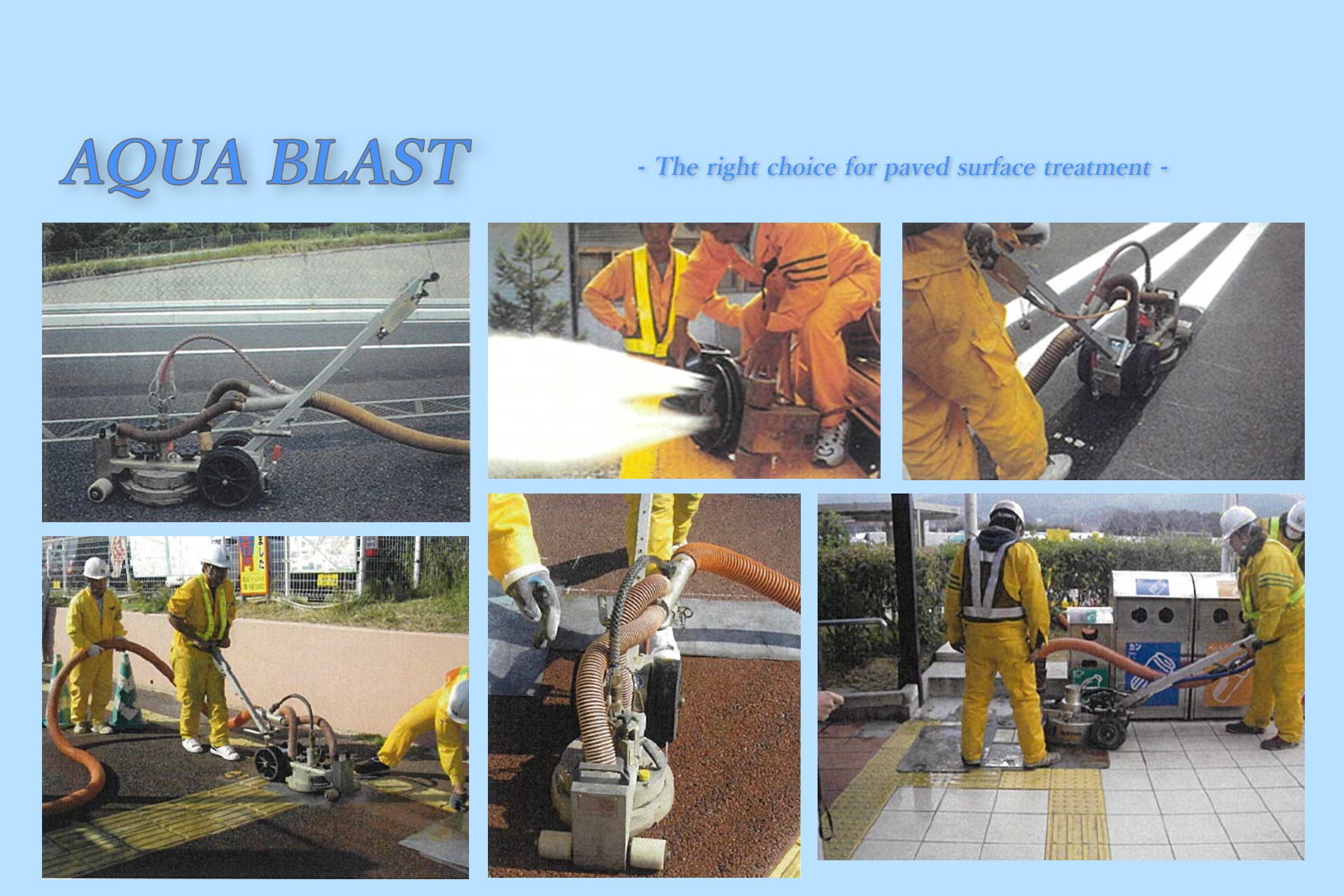

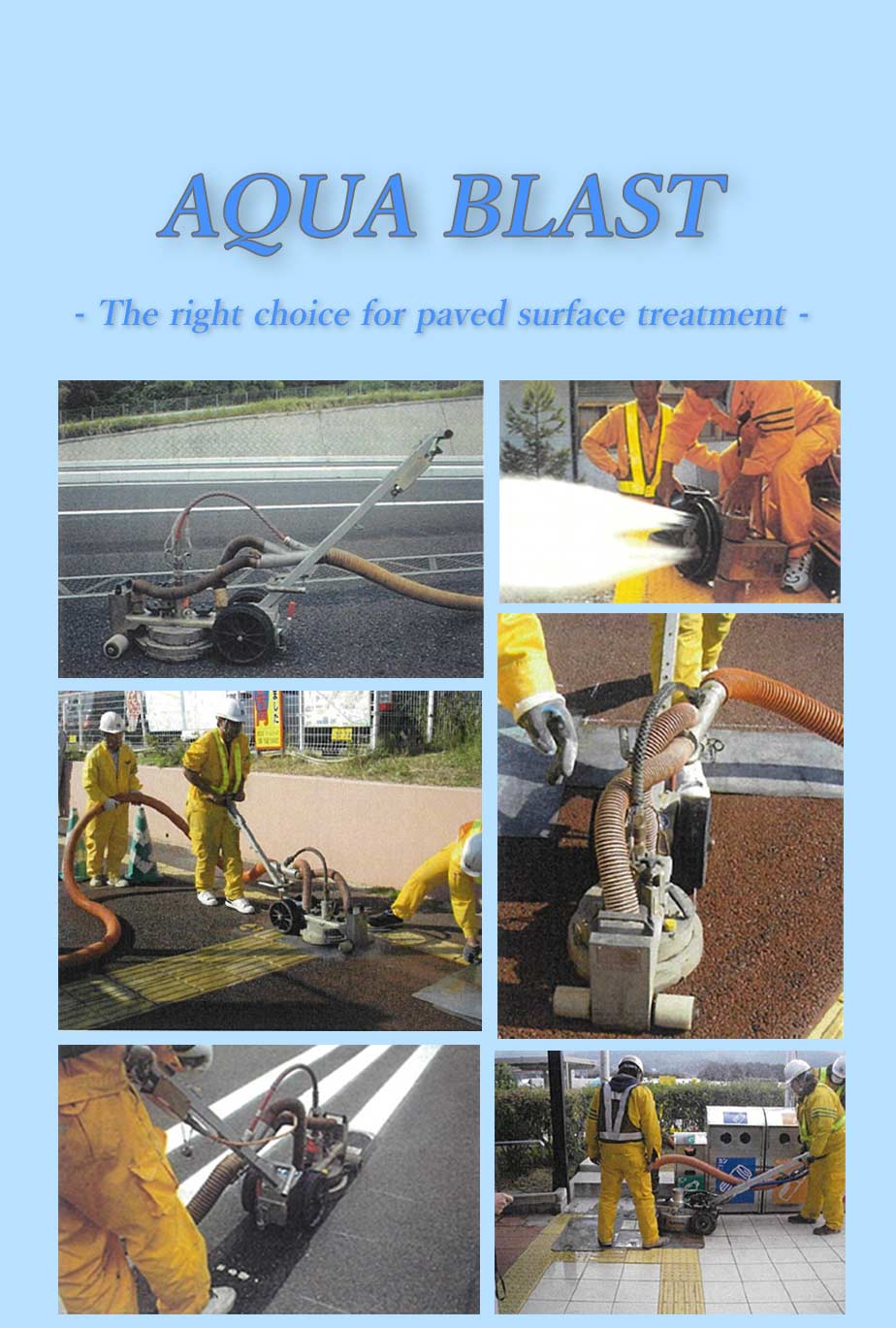

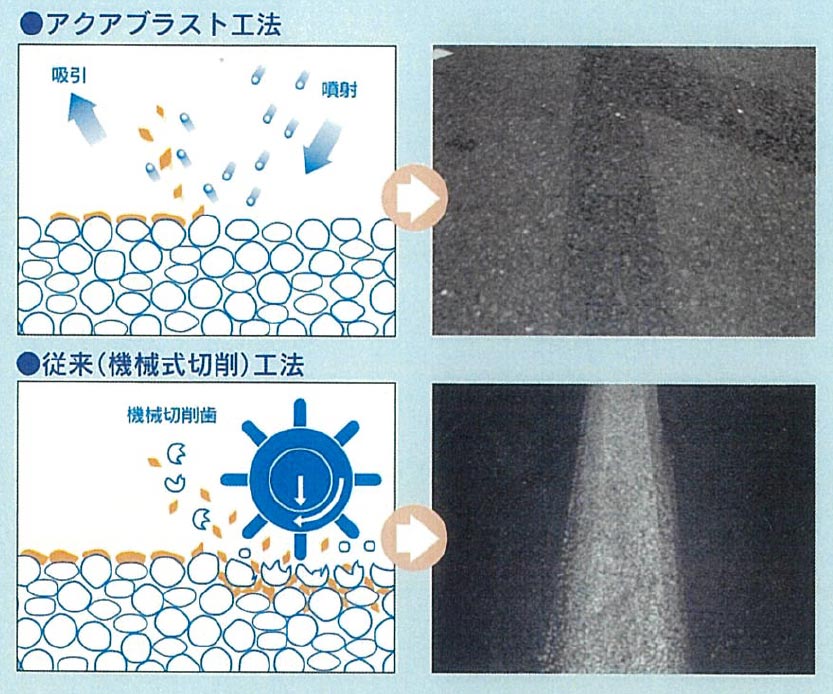

“AQUA BLAST” is a water-blasting machine system used for various purposes such as removing traffic lines and cleaning paved surfaces. It utilizes a high-pressure stream of water that is generated by a high-pressure water pump. The AQUA BLAST can perform traffic marking removal and the waste fluid suction simultaneously, minimizing damage to the paved surface.

■Features

1. Retaining permeable pavement properties

・High-pressure water jet to only peel off coating materials on the permeable pavement, while protecting the pavement surface from unnecessary damage

2. Shorter traffic restriction time

・Allowing the coating material removal and suction simultaneously, thus saving time and labor for work site cleaning

・Making the maintenance work three times more efficient than traditional grinding method

3. Environmentally friendly

・Offering the cleanest way for maintaining pavement surfaces with tap water without using harmful chemicals

・Dividing the waste fluid into clean water and sediment water, ensuring proper waste fluid treatment

4. Smaller machine body makes the maintenance work feasible anywhere and everywhere

・Can be mounted on a 4t truck

・Allows access to narrow spaces, thus covering wider areas as a whole

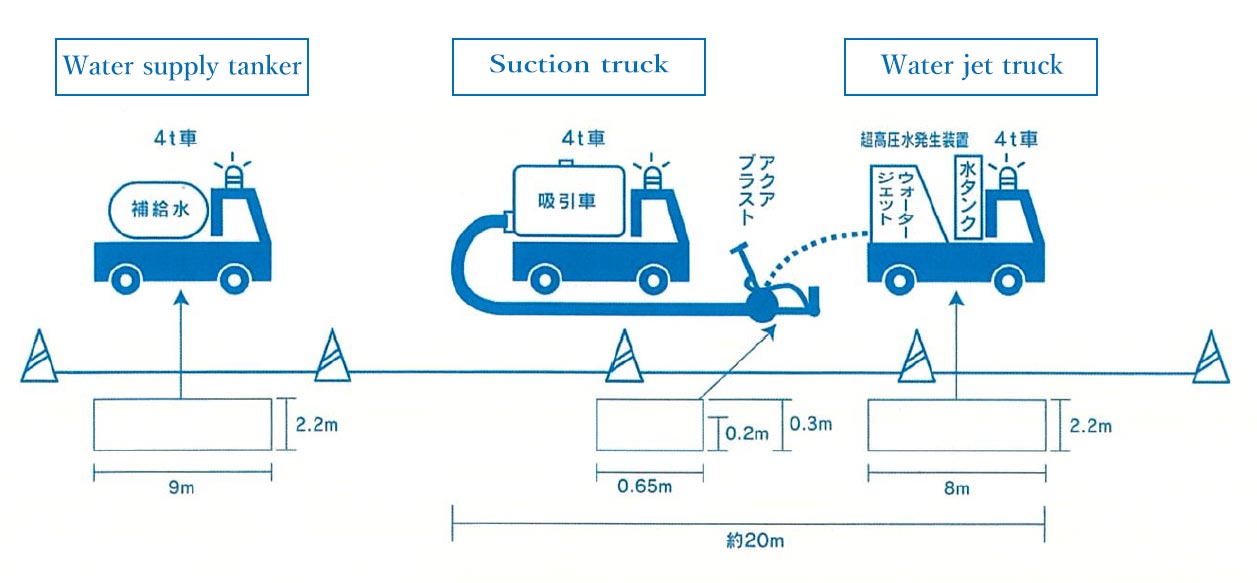

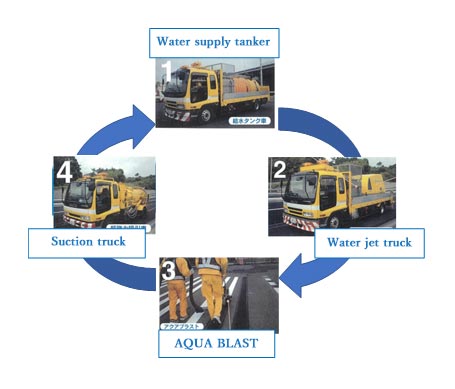

AQUA BLAST System Arrangement

1. In order to use AQUA BLAST, three trucks will be needed.

2. The first truck will carry a water tank and a high-pressure water generator.

The water generator feeds high-pressure water into the AQUA BLAST.

3. The second truck does the suction work by vacuuming the remnant from traffic line removal.

4. The third truck will be the water supply tanker.

Operational Procedure

Result Comparison between AQUA BLAST and Traditional Method

Work Efficiency Comparison between AQUA BLAST and Traditional Method

●AQUA BLAST

●Traditional Grinding Method

The AQUA BLAST system uses apparatus creating less noise, gas emissions, and dust. Thus,it eliminates the need for work site cleaning and avoids troubling the drivers and local residents. The AQUA BLAST achieves more efficient work with less manpower.

The traditional method requires more workers to deal with the dust problems.

In addition, the mechanical noise sometimes causes complaints from the residents.

Work Efficiency Comparison between AQUA BLAST and Traditional Method

●AQUA BLAST

The AQUA BLAST system uses apparatus creating less noise, gas emissions, and dust. Thus, it eliminates the need for work site cleaning and avoids troubling the drivers and local residents. The AQUA BLAST achieves more efficient work with less manpower.

●Traditional Grinding Method

The traditional method requires more workers to deal with the dust problems.

In addition, the mechanical noise sometimes causes complaints from the residents.

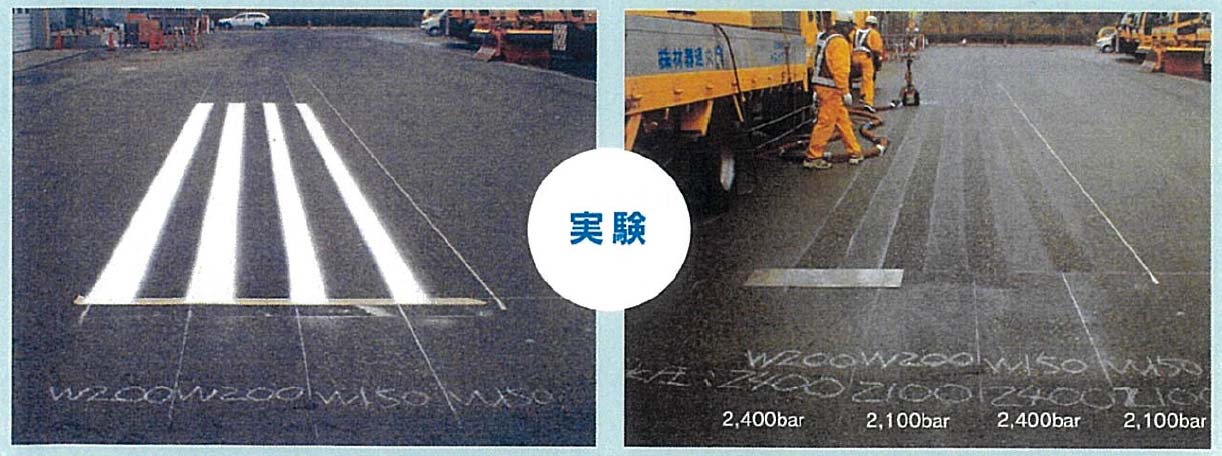

AQUA BLAST’s high performance is proved

AQUA BLAST’s high performance

is proved

An experiment was conducted where the AQUA BLAST removed traffic lines in a MLIT*-compliant pretest.

(Removing traffic lines with 150 and 200-mm widths at 2,100 and 2,400 bar water pressure)

This experiment proves the AQUA BLAST’s excellent performance.

*MLIT: Ministry of Land, Infrastructure, Transport and Tourism

AQUA BLAST Application

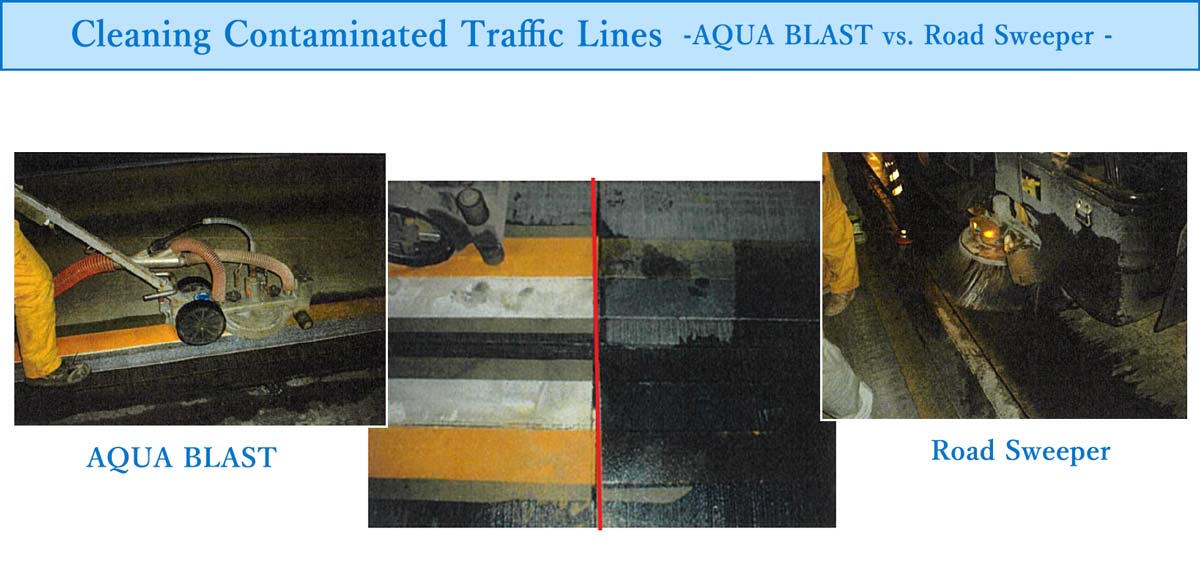

Traffic lines must be visible for road users to ensure traffic safety.

However, the line surfaces are frequently contaminated with exhaust gas, losing their visibility.

The AQUA BLAST and a road sweeper each washed polluted centerlines in this maintenance work.

The result shows that the AQUA BLAST can restore the traffic line visibility even better.

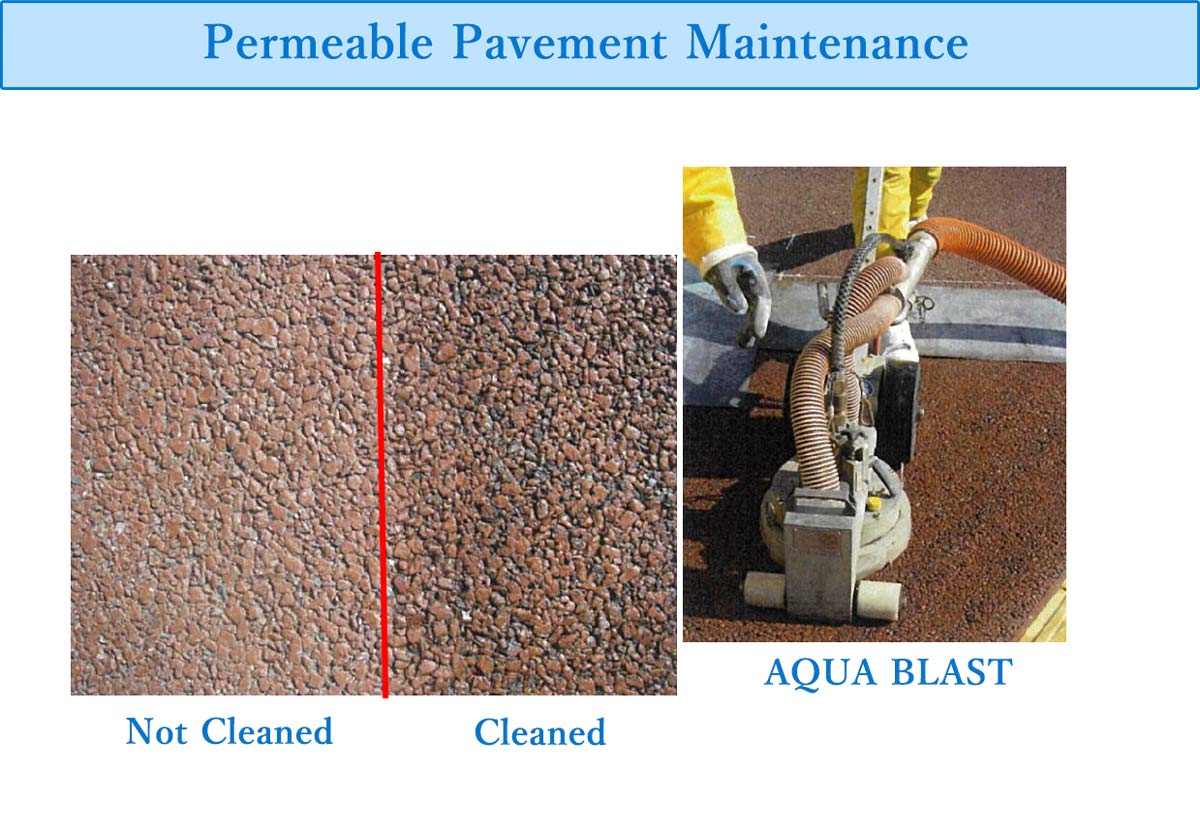

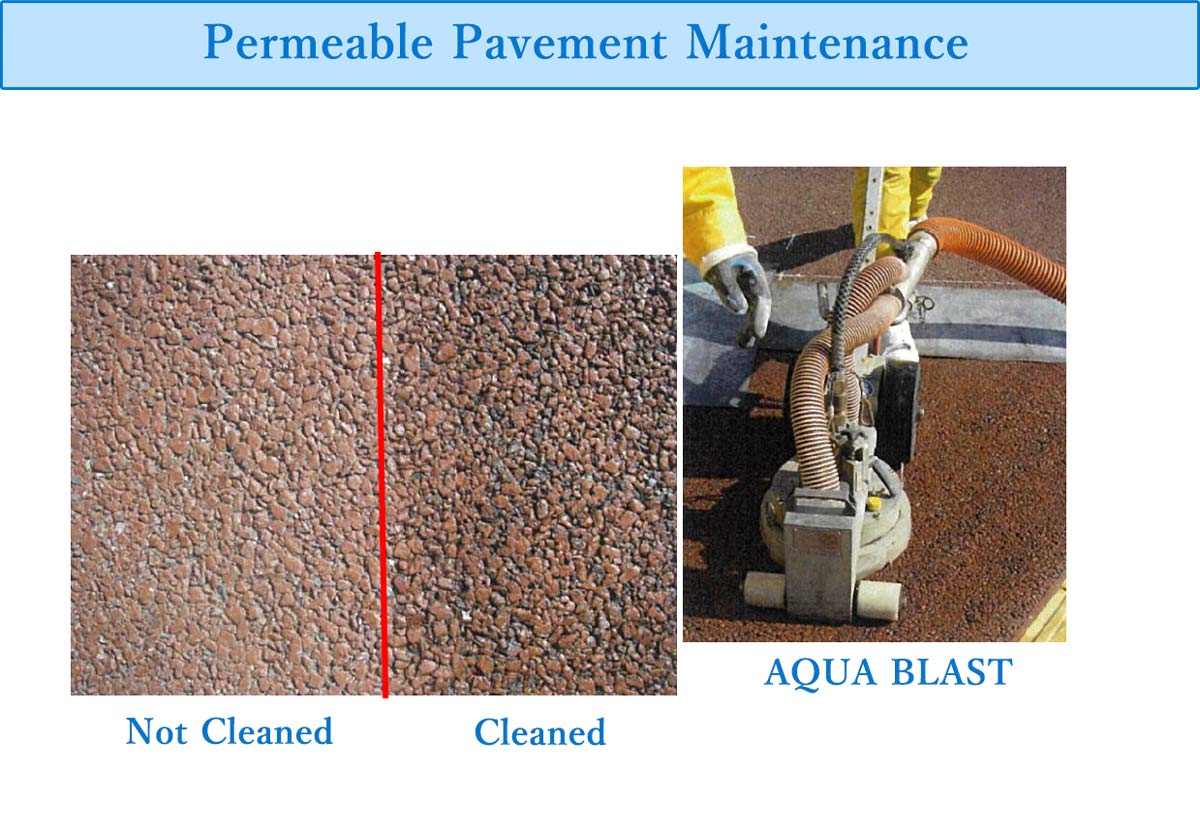

Permeable pavement cleaning is essential to retain its porous property.

Over time, sand and dust gradually clog the pores in surface layers of the permeable pavement, which can cause stormwater runoff. The runoff creates potentially unsafe conditions that may cause pedestrians and cyclists to slip or fall on wet, sometimes icy streets.

AQUA BLAST offers an optimal method to clean the permeable pavement, enhancing road safety.

Permeable pavement cleaning is essential to retain its porous property.

Over time, sand and dust gradually clog the pores in surface layers of the permeable pavement, which can cause stormwater runoff. The runoff creates potentially unsafe conditions that may cause pedestrians and cyclists to slip or fall on wet, sometimes icy streets.

AQUA BLAST offers an optimal method to clean the permeable pavement, enhancing road safety.

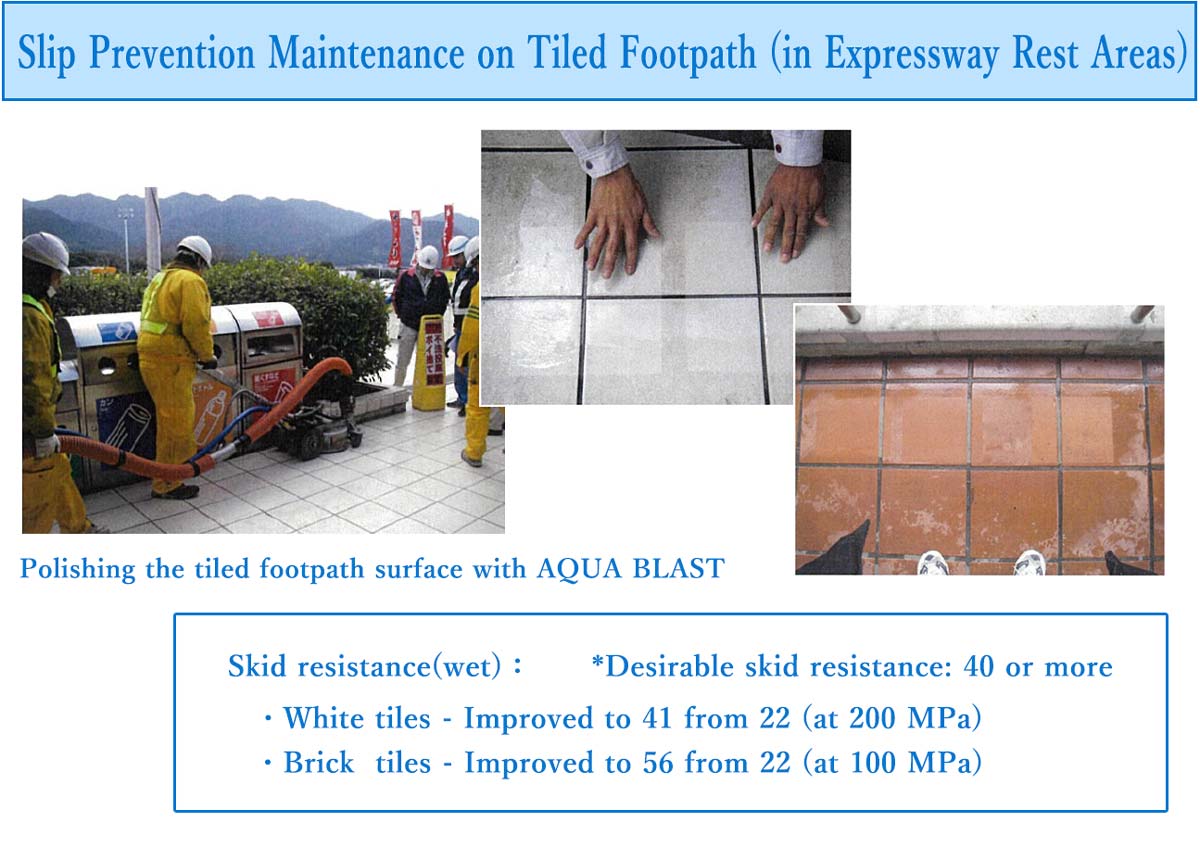

The AQUA BLAST performed surface treatments on abraded footpath tiles in expressway rest areas.

Tile abrasion, which occurs mainly due to the deterioration over time, often causes the pedestrians to slip or fall.

AQUA BLAST’s water jet method can greatly contribute to restore the skid resistance of worn-away tile surfaces.

Product Standards

| Type | Maximum Pressure |

Maximum Flow |

Rotating Speed |

Drive | Dimension | Weight | |

| Total length | Barrel length |

||||||

| NCG8400 | 2,800 bar | 22.7 l/min | 3,000 rpm | air | 630 mm | 450 mm | 5 kg |

| Nozzle | Connection Size |

Air Consumption |

Air Pressure |

| NLB sapphire |

9/16 HP | 630 l/min | 6 bar |

| Type | Maximum Pressure |

Maximum Flow |

| NCG8400 | 2,800 bar | 22.7 l/min |

| Rotating Speed |

Drive | Weight |

| 3,000 rpm | air | 5 kg |

| Dimension | ||

| Total length | Barrel length |

|

| 630 mm | 450 mm | |

| Nozzle | Connection Size |

Air Consumption |

| NLB sapphire |

9/16 HP | 630 l/min |

| Air Pressure |

||

| 6 bar |

Features and Advantages

Application

Copyright © 2018 TEC KINOJYO CO., LTD. All Rights Reserved

Copyright © 2018 TEC KINOJYO CO., LTD.

All Rights Reserved